Manufacturing Centers

One of the fastest growing OEM manufacturers in the industry

- Stamping

- Welding

- CNC

- Drilling/Tapping

- Die-casting

- Tooling

- Surface Treatment

- QC

- Supply Chain

Stamping

This department has the world's leading brand of stamping and drawing production equipment (16T to 250T) and hydraulic stretching machine (80T to 600T). These high-efficient machines can fulfil different clients’ requirements for the design and manufacture of the precision structural parts and high-end exterior parts of various materials. Also, it is a guarantee for providing quality and reliable service for all major famous international brands.

The product material covers stainless steel plate, SPCC, SECC, aluminium plate, copper strips and many other stamped and stretched materials. The product size covers from 1mm to 1200mm. The mold types include single punching, stretching, continuous stamping, which provides efficient, cost-effective, and excellent quality. The product meets the requirements of ROHS, REACH, halogen-free, and FDA, LFGB French/Italian/German requirements for food-grade products in various countries.

equipment introduction

| Specifications | Equipment tonnage | Units of equipment | |||

| AIDA Pneumatic | 63~600T | 20 | |||

| CHINGFONG Pneumatic | 45T~160T | 25 | |||

| GUANGDUAN Pneumatic | 88T~280T | 35 | |||

| GUANGDUAN Hydraulic Stretchinng Machine | 100T~600T | 20 | |||

| Auxiliary equipment (feeder, air compressor, etc.) | 30 | ||||

|

Total

|

130 | ||||

Welding

This center has all kinds of welding, laser engraving, dispensing equipment and production lines, which can provide laser welding, brazing, high frequency induction welding and other laser carving services. With these high-efficient equipment, we can meet clients’ standard and provide reliable guarantee for the quality of services.

Products that we manufactured use different kinds of aluminium, aluminium alloy welding; iron, stainless steel, and other different materials. Almost all the products have high dimensional accuracy, reliable welding, airtight, and beautiful surface appearance. All the products meet the requirements of ROHS, REACH, halogen-free requirements, and FDA for food-grade exposure, LFGB French/Italian/German.

equipment introduction

| Specifications | Device parameters | Units of equipment | |||

| Han's Laser Welding | 2 | ||||

| Argon arc welding equipment | 25 | ||||

| Brazing equipment | 5 | ||||

| High frequency induction welding equipment | 5 | ||||

| Spot welding and welding equipment | 20 | ||||

| Laser laser engraving equipment | 2 | ||||

| Automatic glueing equipment | 1 | ||||

| Iron floor assembly, inspection line | Including air tightness and other reliability tests | 1 | |||

| Heater assembly, full inspection line | Including air tightness and high pressure tests | 2 | |||

| Mop aluminum pipe production line | 1 | ||||

| Peripheral equipment | 87 | ||||

|

Total

|

151 | ||||

CNC

This department has world famous high end brands of top CNC machining equipment, four-axis machines and precision engraving machines, which can fulfil different clients’ various structural materials requirement. With these high-efficient equipment, we can meet clients’ standard and guarantee to produce high precision and cost-efficient products for our clients.

Products that we manufactured use different kinds of aluminium, aluminium alloy welding; iron, stainless steel, and other different materials. Almost all the products have high dimensional accuracy, reliable welding, airtight, and beautiful surface appearance. All the products meet the requirements of ROHS, REACH, halogen-free requirements, and FDA for food-grade exposure, LFGB French/Italian/German.

equipment introduction

| Brands | Device parameters | Units of equipment | |||

| MAZAK | 10 | ||||

| BROTHER | 22 | ||||

| TSUGAMI | 5 | ||||

| DMG | 10 | ||||

| FANUC | 7 | ||||

| HURCO | 1 | ||||

|

Total

|

55 | ||||

Drilling/Tapping

The department has famous international brands of top CNC lathe equipment and various types of ordinary lathe machines. With these machines, we can adapt to the customer's various machining requirements, such as cutting, cylindrical lathe cutting, drilling and tapping, knurling and other complex process. With these high-efficient equipment, we can meet clients’ standard and guarantee to produce high precision and cost-efficient products for our clients.

Products that we manufactured use different kinds of aluminium, aluminium alloy welding; iron, stainless steel, and other different materials. Almost all the products have high dimensional accuracy, reliable welding, airtight, and beautiful surface appearance. All the products meet the requirements of ROHS, REACH, halogen-free requirements, and FDA for food-grade exposure, LFGB French/Italian/German.

equipment introduction

| Specifications | Device parameters | Units of equipment | |||

| MAZAK CNC Lathe | 10 | ||||

| BROTHER CNC Lathe | 5 | ||||

| TSUGAMI CNC Lathe | 5 | ||||

| Automatic lathe | 25 | ||||

| Instrument lathe | 50 | ||||

| Multi-function drilling and tapping machine | 18 | ||||

| All kinds of drilling and attack plane | 2 | ||||

|

Total

|

115 | ||||

Die-casting

This department has well-known brands of top-grade zinc aluminium alloy die-casting production equipment. All machines are equipped with independent furnaces and tonnage ranges from 80T to 800T. With these high-efficient equipment, we can meet clients’ standard and provide reliable guarantee for the quality of services.

The product material contains various die-cast aluminium materials such as ADC12, A360, A380, and 413.2; Zinc alloys (ZAMAK 3 and ZAMAK 5.) The weight of the product ranges from 0.1g to 5000g. All the products that we manufactured meet the requirements of ROHS, REACH, halogen-free, FDA, LFGB French/Italian/German.

equipment introduction

| Specifications | Equipment tonnage | Units of equipment |

| TOSHIBA Alu Casting Machine | 280T~1200T | 10 |

| ZITAI / YIZUMI dense Alu Casting machine | 180T~730T | 22 |

| Zinc Die-Casting Machine | 88T~280T | 15 |

|

Total

|

47 | |

Tooling

This department has a variety of die-casting moulds, punching and stretching mould design capabilities and cutting-edge processing equipment, which can finish mould design and processing in a short period of time.

Mould include aluminium alloy die-casting, zinc alloy die-casting, punching and stretching mould, progressive stamping, and various types of fixtures. The short cycle of processing mold and mature technology makes the mass production more effective and efficient.

equipment introduction

| Specifications | Device parameters | Units of equipment | |||

| Sodick Slow Wire Cut | 2 | ||||

| Sodick EDM | 25 | ||||

| SSG Wire Cut | 5 | ||||

| Lathe | 5 | ||||

|

Automatic grinding machine

|

20 | ||||

| Drilling machine | 2 | ||||

| Self-made mold processing machine and equipment | 87 | ||||

| Total | 146 | ||||

Surface Treatment

This center has a variety of professional dust and explosion-proof polishing production lines, automatic polishing machine, bull-block machine, water mill equipment, light equipment, automatic sandblasting machine, ultrasonic cleaning line. All these machines can complete all kinds of high-grade surface treatment, brushing, mirror effect polishing , water mill, tumbling, sandblasting, cleaning and other high-grade surface treatment.

equipment introduction

| Specifications | Device parameters | Units of equipment | |||

| Automatic polishing production line | 1 | ||||

| Professional environmental protection explosion-proof polishing machine | 80 | ||||

| Professional environmental protection drawing equipment | 25 | ||||

| Automatic sand blasting machine | 5 | ||||

| Water mill equipment | 10 | ||||

| Tumbling equipment | 5 | ||||

| Ultrasonic cleaning line | 3 | ||||

| Peripheral equipment | 50 | ||||

|

Total

|

179 | ||||

QC

This center has various types of precision testing equipment, which can complete all kinds of dimensional inspection, reliability testing, component testing and environmental protection testing. QC provides FAI reports,CPK monitoring, product composition testing, ROHS testing, hardness, tension torque, surface gloss, color deviation, salt spray test, high temperature and humidity, high voltage test, air tightness test and so on.

equipment introduction

| Specifications | Device parameters | Units of equipment | |||

| Hexagon 3D and 2.5D CMM | 2 | ||||

| Light Box, colorimeter, Glossmeter | 3 | ||||

| Projector | 2 | ||||

| High Temperature High Huidity Tester | 5 | ||||

| Rohs Tester | 1 | ||||

| Hardness Tester, Tension Torque Tester | 8 | ||||

| High Pot, Resistance Tester | 2 | ||||

| Air Leakage Tester | 1 | ||||

| Self-made testing equipment and special inspection tools | 130 | ||||

|

Total

|

154 | ||||

Supply Chain

We have all kinds of reliable supply partners who have cooperated for more than ten years. Together, we are the trusted backbone of our success.

equipment introduction

| Types of | Parameter overview | Units of equipment | |||

| Aluminum extrusion | Extrusion machine tonnage 500~4000T | 5 | |||

| Precision injection | Injection molding machine 160T~600T | 3 | |||

| Anodizing, Hard Anodizing | Sandblast and anodizing effect like Apple products, hard anodize | 3 | |||

| Wet Painting, Powder Coatinbg | Automatic Painting line,Dust free cleaning room | 7 | |||

| Electroplating (chrome, nickel, copper, zinc, gold, rose gold) | electrophoretic coating,PVD | 7 | |||

| Cold forging | 2 | ||||

| Others (eg electrophoresis, blackening, etc.) | 15 | 15 | |||

|

Total

|

42 | ||||

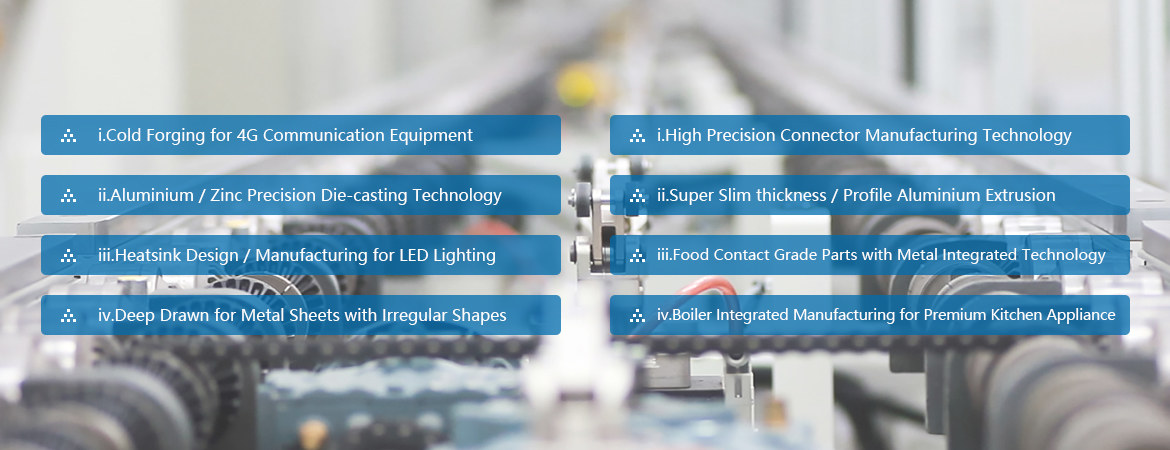

Core Technology

One of the fastest growing OEM manufacturers in the industry

Xiehehui's Future Blueprint

Looking to the future, Xiehehui's new production base factory will invest a huge funding on smart equipment, intelligent management system. Because of the trend of 'Industry 4.0,' Xiehehui will also enter the fields of artificial intelligence, aerospace and other new energy sector.